Have you ever wondered how companies design and build complex products like cars or airplanes? It’s a complicated process, but Siemens is making waves with some new tech that could change the game entirely.

The company is using OpenUSD and NVIDIA Omniverse in tandem to address two key challenges in digital manufacturing: data silos and limited capabilities of digital twins.

Let’s dive into what Siemens is doing using OpenUSD and NVIDIA Omniverse, and why it’s a big deal for the future of manufacturing.

Why is Siemens using OpenUSD and NVIDIA Omniverse?

Siemens is advancing the field of digital manufacturing by incorporating OpenUSD and NVIDIA Omniverse into their workflow. This integration is designed to enhance the photorealism and interactivity of digital twins within Siemens’ Teamcenter X software, which is a component of the Siemens Xcelerator portfolio.

The adoption of OpenUSD facilitates better simulation and analysis, contributing to goals of sustainability and quality. This move is set to improve resource efficiency, reduce waste, and elevate product standards.

For example, Siemens’ flagship electronics factory in Erlangen, Germany, is utilizing this technology to produce varied training datasets for AI models. These datasets are instrumental in tasks such as identifying defects and instructing robots. This demonstrates the transformative impact of digital technologies in manufacturing, with Siemens leading the charge in this evolution.

Here’s a breakdown of why this combo is so powerful:

1. OpenUSD Breaks Down Data Silos:

Imagine different software programs used in manufacturing speaking different languages. That’s essentially what data silos are. OpenUSD acts as a universal translator for 3D scene descriptions.

This means software from various companies can understand and work with the same 3D models seamlessly. No more struggling to convert files or losing valuable data in translation. This fosters smoother collaboration throughout the design process.

2. NVIDIA Omniverse Enhances Digital Twins:

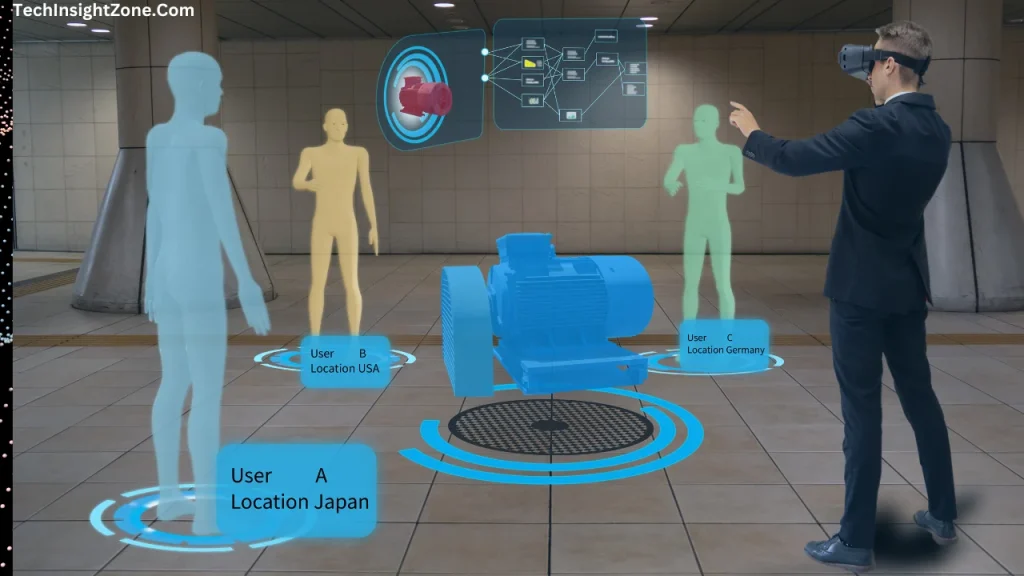

Digital twins are crucial for simulating product performance and identifying design flaws virtually. However, traditional digital twins often lack real-time responsiveness and immersive capabilities. This is where NVIDIA Omniverse comes in. It injects real-time rendering and AI tools into the mix. The result? Digital twins become interactive environments.

Imagine virtually walking through a factory you’re designing or using AI to pinpoint potential weaknesses in a product before it goes into production. This empowers better decision-making and optimizes the entire design and manufacturing cycle.

Combined Benefits:

By using OpenUSD and NVIDIA Omniverse together, Siemens achieves several key goals:

- More Accurate and Versatile Digital Twins: OpenUSD ensures consistent data interpretation across software, leading to more accurate digital twins.

- Enhanced Collaboration: Seamless data exchange through OpenUSD fosters better collaboration between teams using different software.

- Immersive Design and Optimization: NVIDIA Omniverse empowers virtual walkthroughs, AI-driven design optimization, and real-time process simulations.

Overall, Siemens is using this technology combo to create a more efficient and effective digital manufacturing workflow, ultimately leading to higher quality products and reduced costs.

A Glimpse into the Future of Manufacturing

The synergy between OpenUSD and NVIDIA Omniverse presents a transformative vision for the future of manufacturing. Imagine:

- Virtually optimized factories: Production lines can be meticulously designed and optimized within a virtual space before physical construction begins.

- Real-time simulation-driven workflows: Manufacturing processes can be streamlined based on insights gleaned from real-time simulations, enhancing overall efficiency.

- AI-powered training for robots: AI can be harnessed to train robots for specific tasks, ensuring precision and consistency in production.

These advancements translate into a future characterized by reduced waste, superior product quality, and significant cost reductions across the manufacturing value chain.

Challenges and the Road Ahead

Widespread adoption of new technologies often encounters challenges. Gaining industry-wide acceptance for OpenUSD necessitates ongoing collaboration. Furthermore, data security, particularly with complex AI models, requires robust safeguards.

However, Siemens’ leadership in embracing these innovative technologies paves the way for overcoming these hurdles. The integration of OpenUSD and NVIDIA Omniverse signifies a paradigm shift in digital manufacturing, and Siemens is at the forefront of this exciting revolution.

Furthermore, this convergence of cutting-edge technologies not only revolutionizes manufacturing processes but also resonates with the broader narrative of automation’s impact on industries. Delving deeper, explore how packaging robotics are reshaping both packaging and job landscapes, offering a compelling glimpse into the future of production dynamics and employment trends.